PRODUCT

Ductile iron DIN3352 F4 resilient seat gate valve

Designed as Standard : CJ/T216 , DIN3352 , EM1171

Face to Face : GB/T12221-3 ; DIN3202-F4 ; ANSI/ASME B16.10

Flange as Standard : GB/T17241.6-1998 ; DIN2632/2633;BS4504;

can be use JIS-B2220 and ASME B16.5

Test as Standard : GB/T13927-2008; BS EN12266-1 12266-2

Product profile :

The opening and closing part of the gate valve is the gate plate. The movement direction of the gate plate is perpendicular to the direction of the fluid. The gate valve can only be fully opened and fully closed, and can not be adjusted and throttled. The gate plate has two sealing faces. The two sealing faces of the most commonly used mode gate valve form a wedge. The wedge Angle varies with the valve parameters, usually 50, and 2° 52'' when the medium temperature is not high. The gate of wedge gate valve can be made into a whole body, called rigid gate; It can also be made into a gate that can produce trace deformation to improve its technology and make up for the deviation of the sealing surface Angle in the process of processing. This gate is called elastic gate and is generally connected by flange.

Features :

1. The wearing parts gasket is made of EPDM rubber as the sealing material, which has reliable sealing and long service life.

2. The gate is entirely covered with glue, and its good covering performance and precise geometric dimensions ensure reliable sealing.

3. The valve body and bonnet are made of ductile iron, which is light in weight and easy to install.

4. The bottom adopts the same flat-bottom valve seat design as the water pipe, which does not cause debris accumulation and ensures reliable sealing.

5. The inner and outer cavities are made of non-toxic epoxy resin to prevent corrosion and rust. It is not only suitable for raw drinking, but also can be used in sewage systems

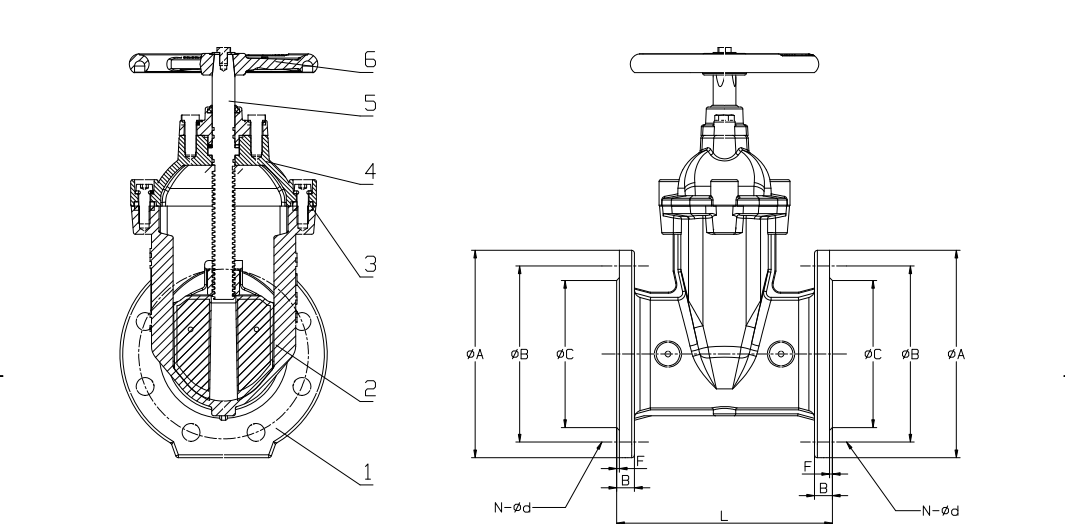

Dimension Table :

| DN | L | ØA | ØB | B | ØC | N-Ød | F |

| DN40 | 140 | 150 | 110 | 19 | 84 | 4*Ø19 | 2 |

| DN50 | 150 | 165 | 125 | 19 | 99 | 4*Ø19 | 2 |

| DN65 | 170 | 185 | 145 | 19 | 118 | 4*Ø19 | 2 |

| DN80 | 180 | 200 | 160 | 19 | 132 | 8*Ø19 | 2 |

| DN100 | 190 | 220 | 180 | 24 | 156 | 8*Ø19 | 2 |

| DN125 | 200 | 250 | 210 | 24 | 184 | 8*Ø19 | 2 |

| DN150 | 210 | 285 | 240 | 24 | 211 | 8*Ø23 | 2.5 |

| DN200 | 230 | 340 | 295 | 25 | 266 | 12*Ø23 | 2.5 |

| DN250 | 250 | 395 | 355 | 28 | 319 | 12*Ø28 | 2.5 |

| DN300 | 270 | 460 | 410 | 28 | 370 | 12*Ø28 | 3 |

| DN350 | 290 | 520 | 470 | 30 | 429 | 16*Ø28 | 3 |

| DN400 | 310 | 580 | 525 | 30 | 480 | 16*Ø31 | 3 |

| DN450 | 330 | 640 | 585 | 34 | 548 | 20*Ø31 | 3 |

| DN500 | 350 | 715 | 650 | 34 | 609 | 20*Ø34 | 3 |

| DN600 | 390 | 840 | 770 | 36 | 720 | 20*Ø37 | 4 |