Wafer butterfly valve

Concentric wafer butterfly valve is the most commonly used wafer type butterfly valve .The butterfly valve disc is centered on the butterfly valve stem to ensure even sealing around the valve.

The function is to maintain a seal to prevent bidirectional pressure differences in fluid flow. To avoid any backflow in a system built for unidirectional flow. This is achieved through the use of tight-fitting seals (e.g. precision machined O-rings, gaskets) and flat valve faces on the downstream and upstream portions of the valve.

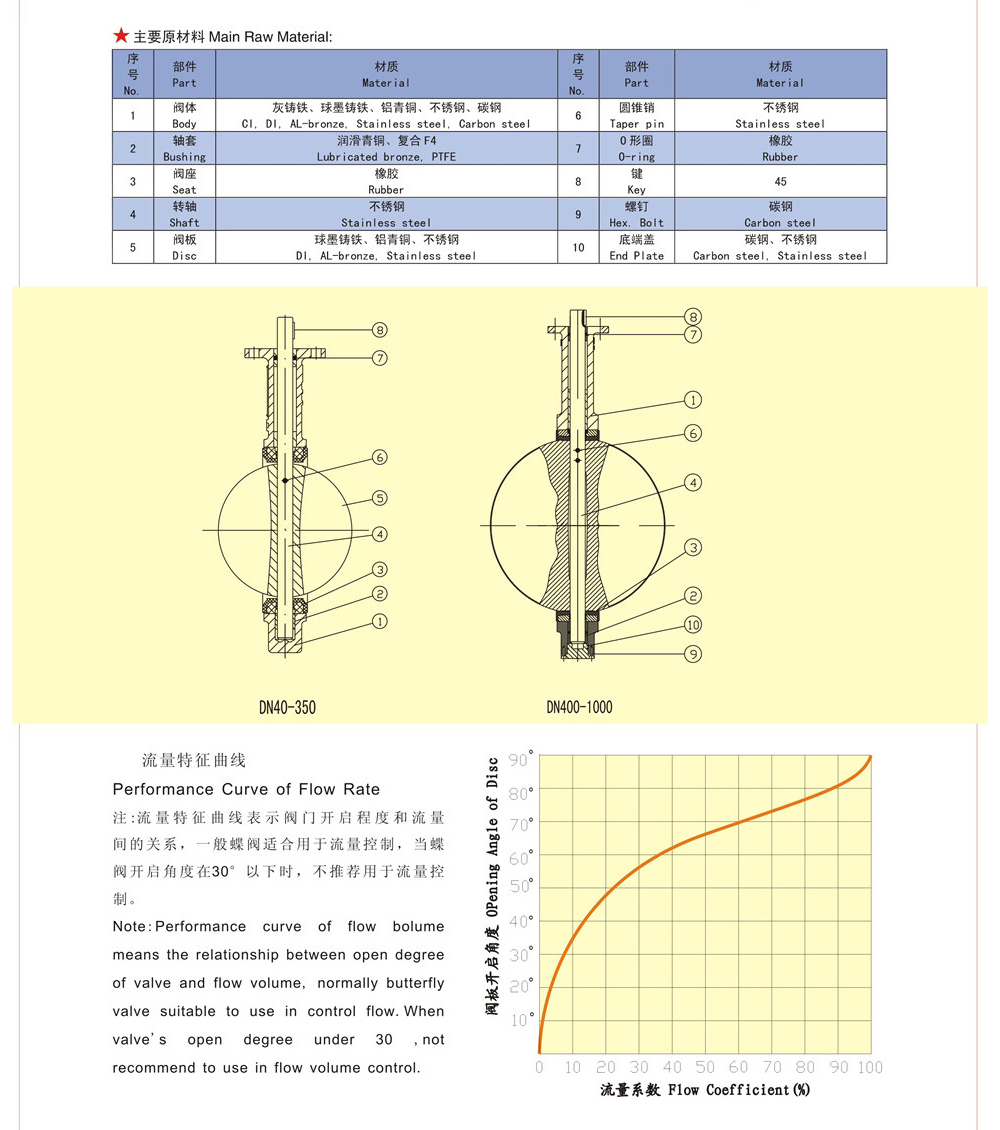

Wafer butterfly valve is mainly composed of valve body, valve plate, sealing ring, low-pressure bolts, valve stem, etc. Among them, the main part of the wafer butterfly valve is pointed out. Generally made of cast iron and stainless steel, it has extremely high corrosion resistance and pressure resistance. The butterfly valve plate is the key internal component of the wafer butterfly valve, and its material is usually cast iron, stainless steel, stainless steel, etc. The sealing ring is a key component of the wafer butterfly valve. It mainly plays a sealing role. The hard sealing ring can adapt to high temperature and elegant environments, while the soft sealing ring is suitable for low pressure and normal temperature environments. The clamping bolt is mainly used for the front valve plate and sealing ring, and the key component of the valve stem connecting the valve plate and handle.