PRODUCT

Slip butterfly valve wafer style PFA seat and Disc

Size : DN50-600

Face to Face dimension: GB/T12221 EN 558-1-20 ,ISO5752-20, API609 Table 2

Flange end : HG/T 20592 PN10/16, EN1092 PN10/16, ASME B16.5 150LB

Sealing Face : DIN2526 Form A-E , ANSI B16.5 RF, FF

Top Flange: ISO5211

Work pressure :10bar

Temperature : -20℃--180℃

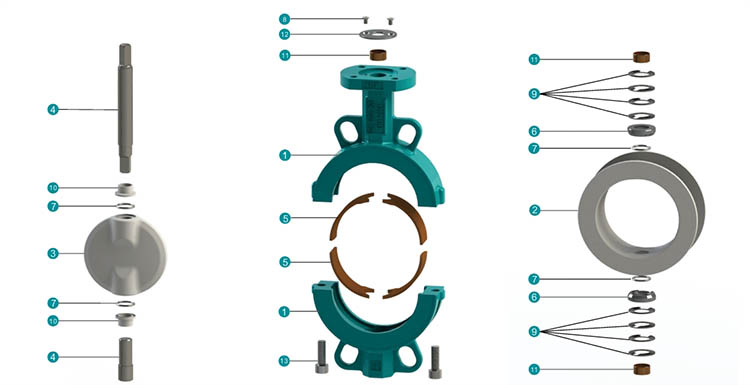

Material:

| 1 | Body | Cast Iron(GG25), Ductile Iron(GGG40/50), Carbon Steel(WCB A216), Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze |

| 2 | Seat | NBR, EPDM/REPDM, PTFE/RPTFE, Viton, Neoprene, Hypalon, Silicon, PFA. |

| 3 | Shaft | SS416, SS431, SS304, SS316, Duplex Stainless Steel, Monel |

| 4 | DIsc | DI+Ni, Stainless Steel(SS304/SS316/SS304L/SS316L) , Duplex Stainless Steel(2507/1.4529), Bronze, (DI/WCB/SS) coated (Epoxy Painting/Nylon/EPDM/NBR/PTFE/PFA) |

| 5 | Pin | Stainless Steel |

| 6 | Bushing | PTFE, Bronze |

| 7 | O Ring | NBR, EPDM, FKM |

| 8 | Operation | Hand Lever, Gear Box, Electric/Pneumatic/Hydraulic Actuator |

Features:

1. Seat and body are split design for easy maintenance and replacement.

2. The valve body is designed to be open and the axial seal is safer.

3. It adopts an anti-exit structure for valve stem, spring +U type card structure are used in the upper part of the stem, which can not only compensate for installation errors, but also prevent the stem from loosening.

4. Valve plate and seat seal are of ball design, more reliable sealing.

5. Design elastic mechanism at seat end to compensate sealing effect of seat and valve plate.